Description

Introduce

Remote terminal unit (RTU) is a specific computer unit with modular structures for measuring and controlling in long-distance communication in complex industrial environments. In the automative dispatching system of the power grid , RTU installed in power plants and substations plays a significant role as an automatic terminal in telecontrol, remote signaling, telemeter and remote adjusting.

Dongfang Electronics has been devoted to providing users with more stable, reliable, flexible and economical RTU products over the years.

Functions of DF1725IED RTU

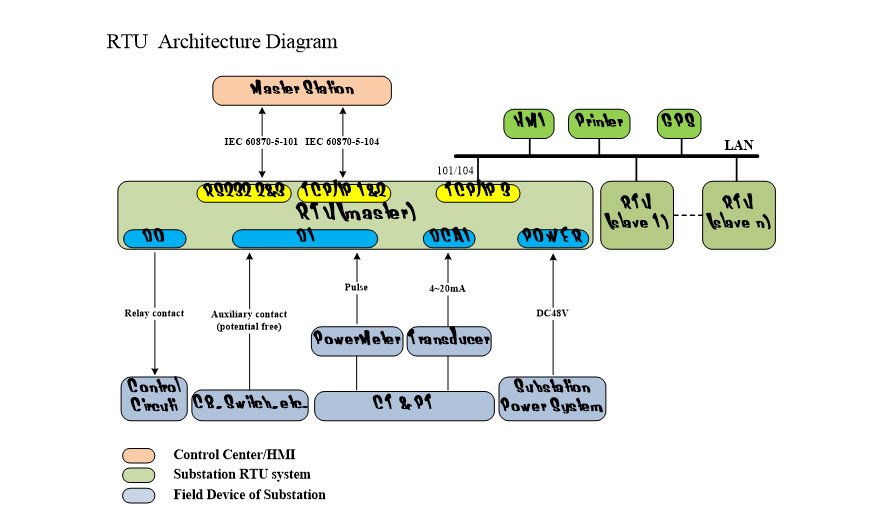

With a plot structure, DF1725IED RTU connects each plug-in unit and the main control unit by parallel bus. The external box can be extended by the Ethernet port. Its size is 19 inches, which is suitable for specified installation of cabinets by both distributed and integrated approaches.

The following functions are available

1.Remote monitoring and control: It is achieved based on the information interaction between RTU and control center.

1.1. Digital inputs (Remote signaling):

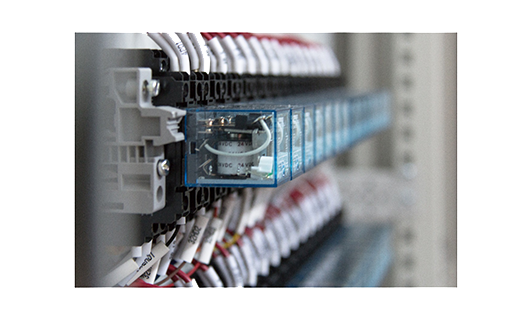

Working states of the stations and plants including the positions of circuit breakers and switches of lines and transformers, alarm signals of the relay protection devices and etc are collected and delivered to the control center by the RTU.

1.2. Digital inputs (Telecontrol):

RTU can change working states of the equipment in the plants and stations according to the instructions of the control center by manipulating the circuit breakers of various voltage levels, linking and removing corresponding units and etc.

1.3. Analog input (Telemeter):

RTU can collect operational parameters of the plants and stations including currents, voltages, active powers, reactive powers, gears, temperatures and etc, then send them to the control center.

Data acquisition modes:

1.3.1 Directly collecting: RTU can collect the current and voltage signals connected.

1.3.1.1 DC sampling: The RTU can receive the DC signals from the transmitter, for example, 4-20mA, 0-5V signals and etc.

1.3.1.2 AC sampling: RTU is directly connected to AC voltages and currents of CT and PT without a transmitter, for example, 1/5A, 100/110V.

1.3.2 Digital acquisition: The signals collected by RTU are some pulses and the number of them is accumulated. This is generally used in electrical metering.

1.4. Analog output (Remote adjusting): RTU can adjust operational parameters of the equipment according to the central commander, for example, the gear of the transformers and the outputs of the generator set.

1.5. SOE (Sequence Of Events) recording: RTU can detect the changes of remote signals and record the changing time, linked devices, status and etc.

1.6. Time synchronization: RTU can adjust its internal clock to be consistent with the master station according to the commands of the control center or GPS.

1.7. The RTU can get access to the information collected by other smart IED devices through protocol and send it to the main station.

1.8. The RTU can achieve information interaction with the control center and local backstage by 101/104/DNP3 protocols.

1.9. Self check and fault locating: The device can check itself, generate information documents and alarm, which is so-called “watchdog”. Restart and initialization will be proceeded when there is a fault. Moreover, the location of the abnormal plug-in unit can be detected.

1.10. Configuration and maintenance

General web browsers can be used for configuration and parameter modification of the RTU. For further operations, professional maintaining software are available.

2.On-site function: Independent monitor in RTU

2.1. On-site displays and one-button handling:

Data browsing, parameter modifying, controlling and operating, clock viewing and adjusting can be proceeded in real time on the LCD screen and by the buttons.

2.2. Indicating the working states: The status of plug-ins, receiving and sending status of communication interfaces and etc are indicated by relative LED lights, contributing to effective maintenance.

Technical Highlights of DF1725IED RTU

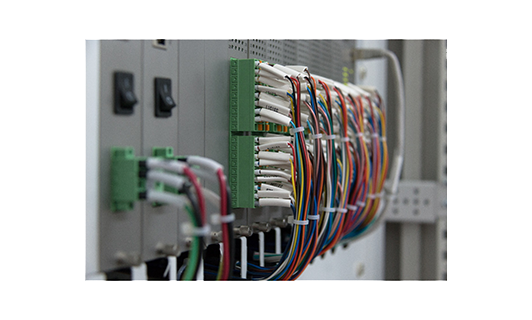

• The device is equipped with advanced industrial-class chip. Its hardware system with strong reliability is designed in strict accordance to the international specifications, achieving electrical isolation, electromagnetic shielding and strong capability of anti-interference.

• Embedded 32-bit processor presents high systematic processing performances.

• CPLD technology simplifies the design of circuit boards and improves product stability.

• 16-bit high-speed A / D conversion chip with synchronous sampling technology ensures high measuring accuracy.

• Aimed at redundancy design, the RTU is equipped with an auxiliary set of CPU, two power supply devices and two communication interfaces, guaranteeing the stability of the operation and the effective interactions between devices.

• Remote maintenance and configurations are available.

• It supports PLC functions conforming to IEC61131-3.

• A variety of self-checking and error-alarming functions can monitor and control the real-time working status of the equipment.

• Reliable EMC of the RTU contributes to its strong adaptability to severe environment.

• Various communication ports including RS232 / RS485 / Ethernet port are accessible and scalable.

• Various international communication protocols including iec60870-101 / 103 / 104, DNP3, MODBUS and etc are available.

• Safe and reliable, the device is designed in strict accordance to the network security requirements in IEC 62351.

• It has a broad adaptable range of temperatures among – 40 ℃ ~ 70 ℃.

• Modular design and unified interfaces effectively result in its flexible installations, easy replacements, and high cost efficiency.

• External cabinet with diversified sizes, including 19 inches,s can fit different installation locations.

RTU Architecture Diagram